Work Environment

Lung Cheng has advanced machinery and a structured workspace, with dedicated areas for molds, raw materials, production, and inspections, ensuring efficient and safe production.

On-site Environment

Mold Storage

Raw Material Storage

Inspection Room

Mold Factory

Our mold area features precision equipment like EDM, milling machines, lathes, and grinders to ensure mold production meets required standards and efficiency.

Grinder

Lathe

Electrical Discharge Machine

Milling Machine

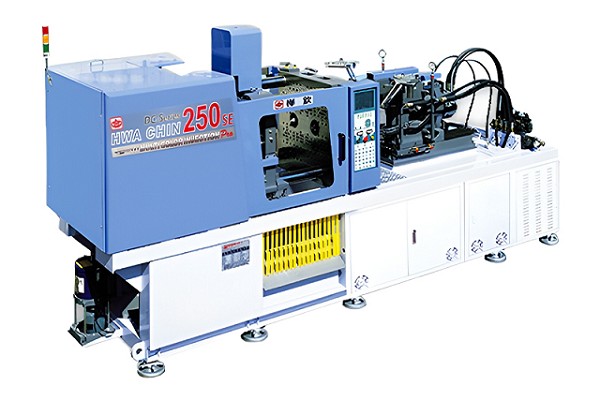

Machinery Equipment

We have 17 plastic injection machines from 90 to 400 tons, including vertical, two-color, and large horizontal machines, ensuring versatile and efficient production.

Computerized Automatic Injection Machine

Two-Color Computerized Injection Machine

Large Horizontal Injection Machine